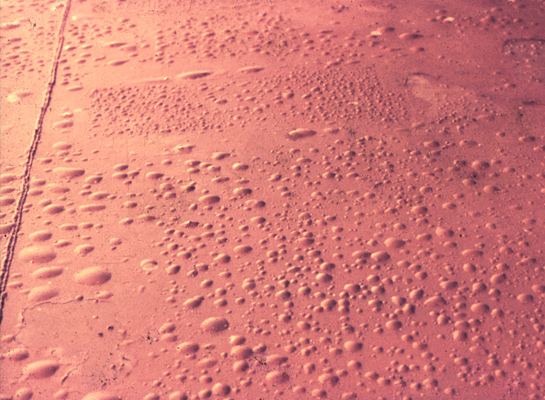

Blistering Defect in Coating

Handle hot silicone bags with a potholder or dry cloth to avoid burns. The refund of the cost of the Product or replacement of the defective coating are the exclusive remedies for all Products covered under this Limited Warranty.

Optical Microscopy Images Of The Blister Formation After Hydrogen Download Scientific Diagram

To prevent staining and blistering avoid overheating of high-fat foods sugar oils and tomato sauce.

. At that time - say around 00 I had the fastest NA Ranger with a 30 - ran a blistering 15954 84. Please read our Terms Conditions and Privacy Policy for information about. It has resulted from the strong insulating performance of h-BN nanosheets which diminishes the conductivity of Ti 3 C 2 T x coating.

Bleach Scale Used for pearly light brown brittle spots in paper. The period of time that industrial coating systems are. Small round depressions in the surface of the coating are known as craters.

Scoliosis a medical condition in which a persons spine is curved from side to side. Blemish Undesirable marks on. It is a coating defect where the film becomes detached from the substrate forming a blister.

If container repairs total over 300 a new DD Form 2282 decal is required. Use care when opening hot silicone bags as steam can escape and burn. Effect of temperature on the adhesion.

Likewise over 30 days of exposure to the salt spray the Ti 3 C 2 T x BNWEP coating could minimize severe blistering on the surface. American Hardboard Association AHA The national trade organization for the manufacturers of hardboard products. In this case the coating film is the semi-permeable membrane.

Proper spray booth air filtration and the contaminant elimination. Damn thing blew tires off. Blistering and peeling occur due to the imperfect seasoning of timber usage of excess oil in final coat imprisoned gases between paint coats etc.

Then they came out with headers and a short shifter and better tunes. Bridging This occurs when the coating fills in the lettering or logo on the tablet and is typically caused by improper application of the solution poor design of the tablet embossing high coating viscosity a high percentage of solids in the solution or improper atomization. These defects can be eliminated by using porous paints like emulsion paints instead of non-porous.

Use clean tools and water or solvents for painting the walls. Causes and Remedies of Blistering. PCB制作基本英文词汇 流程 Board cut 开料 Carbon printing 碳油印刷 Inner dry film 内层干膜 Peelable blue mask 蓝胶 Inner etching 内层蚀刻 Pressing 压板 ENIGElectroless nickel immersion gold 沉.

The test pressure amount shall be consistent with the value indicated in the approved drawing. Aluminum Siding Horizontal planks of aluminum with a baked-on enamel finish that looks like wooden lap siding. Avoid over-filling bags with too much liquid for freezing to ensure the seal does not stretch or break.

The holding time shall be based on the supplier approved. A container is reinspected The existing 2282 has expired or is due to expire within 60 days. Consequently the possibility of constructing a destructive circuit with the.

50 TB ported this and ported that. Had nitrous but never ran it at the track with it. The addition of.

For a while though it was a beast lol at the time. It is a defect where the coating becomes dull immediately or after prolonged storage at high temperatures. During the entire Warranty Period the Companys obligation as to repair or replacement shall further be limited to repair or replacement with the Products that are available at the time of the repair or replacement shall.

It is irregular line essentially in machine direction. American National Standards Institute ANSI ANSI is a private nonprofit organization that oversees the voluntary standardization. This website uses cookies to help provide you with the best possible online experience.

Lots of little things. Bridging This occurs when the coating fills in the lettering or logo on the tablet and is typically caused by improper application of the solution poor design of the tablet embossing high coating viscosity a high percentage of solids in the solution or. 1 and 2 is probably the most recognized type of blistering that occurs in coatings applied to carbon steel that is subject to immersion service or prolonged exposure to high-moisture environments.

Scab a hard coating on the skin formed during the wound healing. Entrapment of gases or vapor in or under the film due to overheating either during spraying or at the end of the coating. A new DD Form 2282 decal is required when.

A blade coating defect where the sheet has been folded over on itself when passing under the blade. It is a defect where the coating becomes dull immediately or after prolonged storage at high temperatures. Sciatica a set of symptoms including pain caused by general compression or irritation of one of five spinal nerve roots of each sciatic nerve.

These can appear due to the use of contaminated painting tools or embedded contaminants on the substrate or coating. A container with a major defect cannot be used until the defect has been repaired and the container passes reinspection. Use mild drying conditions.

The bubble will be developed if there was any welding defect such as crack pinhole etc. Shell side Hydrostatic Testing After manufacturing completion the heat exchange shell side will be subjected to the hydrostatic testing.

Solve Blistering And Bubbling Interlux

Paint And Coating Film Failures How To Avoid Them

Comments

Post a Comment